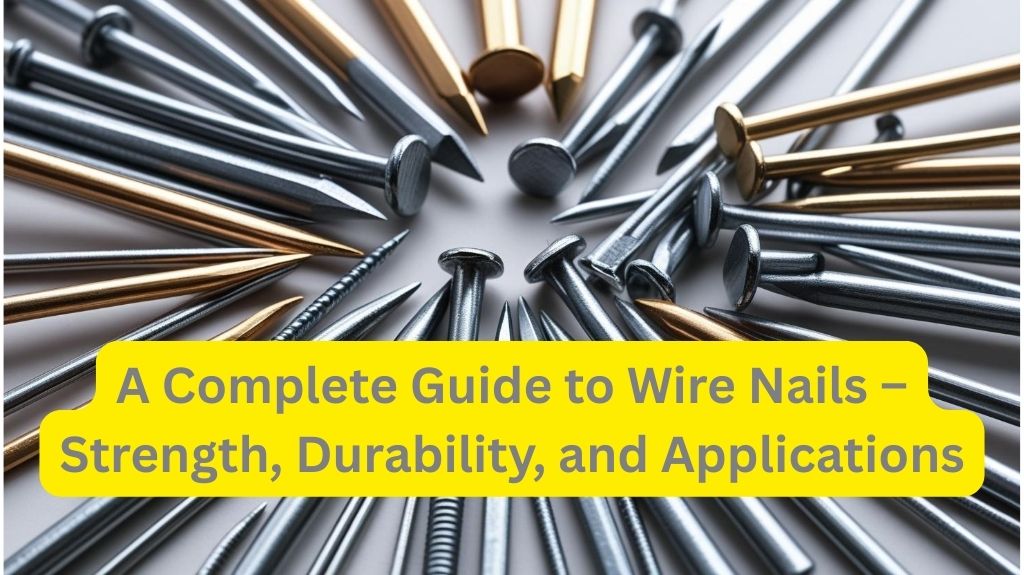

A Complete Guide to Wire Nails – Strength, Durability, and Applications

A Complete Guide to Wire Nails – Strength, Durability, and Applications

When it comes to construction, woodworking, or industrial projects, the right fastening solution can make all the difference. Wire nails, though often overlooked compared to more complex tools, are the backbone of countless building and fastening applications. Known for their strength, versatility, and affordability, they remain a trusted choice for contractors, craftsmen, and industries across the USA.

At WIREHANGERS.US we take pride in manufacturing and supplying premium-quality wire nails and coil nails nationwide. With cutting-edge production facilities, strict quality standards, and competitive bulk pricing, we ensure our customers receive consistent, durable, and high-performance fastening solutions.

What Are Wire Nails?

Wire nails are produced from drawn steel wire, shaped with precision to ensure uniformity, high tensile strength, and resistance to bending. Unlike traditional cut nails, wire nails provide stronger holding power and compatibility with modern nail guns, making them the preferred choice for construction contractors, industrial projects, and woodworking professionals.

Key Strengths of Wire Nails

Wire nails are valued for qualities that make them a staple in large and small projects alike:

-

Long-Lasting Durability – Tough enough to withstand the demands of heavy-duty construction.

-

Superior Holding Power – Variants like thread nails and ring shank designs ensure a strong grip.

-

Corrosion Resistance – Galvanized and coated nails stand strong in both indoor and outdoor environments.

-

Efficiency & Speed – Options like coil nails and plastic strip nails are designed for rapid use in automated framing and roofing systems.

-

Wide Applications – Perfect for everything from framing houses and decking to anchoring into concrete or masonry.

Types of Wire Nails and Applications

At WIREHANGERS.US, our product range is designed to cover diverse fastening needs:

1. Coil Nails

-

High Durability | Crafted from premium steel for long-term performance.

-

Rust-Resistant | Protective galvanized coatings prevent corrosion.

-

Best Used For | Roofing, fencing, framing, and high-speed construction.

2. Thread Nails

-

Enhanced Grip | Spiral or ring shank prevents loosening over time.

-

Durable Build | Retains strength under heavy loads.

-

Best Used For | Woodworking, furniture projects, and heavy carpentry.

3. Concrete Nails

-

Ultra-Hard Build | Made from hardened steel for masonry penetration.

-

Reliable Anchoring | Secure hold in tough materials.

-

Best Used For | Brick, stone, drywall anchoring, and concrete structures.

4. Plastic Strip Nails

-

Fast & Smooth | Designed for modern nail guns with precision spacing.

-

Custom Fit | Ideal for contractors handling large projects.

-

Best Used For | Framing, decking, sheathing, and industrial fastening.

Why U.S. Clients Benefit From Bulk Wire Nail Orders at WIREHANGERS.US

As both a manufacturer and supplier of wire nails in the USA, we give our domestic clients a competitive edge with:

1. Factory-Direct Pricing

-

By ordering directly from the manufacturer, clients avoid middlemen and gain greater cost savings.

-

Bulk buyers enjoy wholesale rates tailored for contractors, distributors, and industrial suppliers.

2. State-of-the-Art Manufacturing Facility

At WIREHANGERS.US, our in-house production strength ensures consistency, quality, and scale unmatched in the industry. Our infrastructure includes:

-

High-speed wire nail forming machinery ensuring precision.

-

Automated galvanizing and coating lines for long-lasting rust resistance.

-

Rigorous quality control checkpoints during every manufacturing stage.

-

Custom nail size and finish capabilities for client-specific needs.

3. High-Volume Capabilities

-

We cater to large orders – whether you need 10,000 nails or 10 million, our facility is designed for round-the-clock production and fast delivery.

-

Perfect for construction companies, industrial suppliers, and wholesale distributors looking for consistent bulk supply.

4. Reliable & Timely Delivery

-

Our streamlined workflow, supervised teams, and efficient logistics ensure on-time delivery across the U.S.

-

We are equipped to meet recurring supply contracts for distributors and nationwide projects.

5. Dedicated Customer Support

-

From technical assistance to bulk order customization, our specialists are here to guide clients to the right product for every application.

Final Thoughts

Wire nails remain one of the most cost-effective and reliable fastening solutions in modern construction, woodworking, and industrial projects. By choosing WIREHANGERS.US, U.S. clients not only get premium-quality nails built for strength, durability, and precision but also enjoy the benefits of working with a domestic manufacturer offering bulk supplies, factory-direct pricing, and world-class infrastructure.

Contact WIREHANGERS.US today to place your bulk wire nail order and secure the best deals in the U.S. fastening industry!

Frequently Asked Questions (FAQ) About Wire Nails

1. What are wire nails used for?

Wire nails are widely used in construction, woodworking, furniture making, roofing, and industrial applications. They provide strong holding power and durability, making them suitable for framing, decking, concrete anchoring, and fencing projects.

2. Are wire nails stronger than common cut nails?

Yes. Wire nails are typically stronger and more uniform than cut nails because they are manufactured from drawn steel wire. This gives them higher tensile strength, precision, and resistance to bending, especially in heavy-duty applications.

3. Which type of wire nail is best for concrete or masonry?

For concrete, stone, or brickwork, concrete nails are the best choice. Made from hardened steel, they can penetrate tough surfaces and provide secure anchoring, even in demanding environments.

4. Do wire nails resist rust and corrosion?

Yes. At WIREHANGERS.US, many of our nails come in galvanized or coated finishes that protect against corrosion, making them ideal for outdoor and long-term applications in harsh weather conditions.

5. Why should U.S. contractors buy bulk wire nails from WIREHANGERS.US?

By ordering directly from us (a domestic manufacturer and supplier), U.S. contractors get:

-

Factory-direct pricing without middlemen

-

High-volume capacity for large projects (10,000–10 million nails)

-

Custom sizes & coatings for specialized needs

-

Fast & reliable nationwide delivery

6. What’s the difference between coil nails and plastic strip nails?

-

Coil nails: Arranged in a coil, they are best for roofing, fencing, decking, and high-speed automated nailing machines.

-

Plastic strip nails: Held together with plastic strips, they provide precise alignment and are ideal for framing, sheathing, and decking.

7. Can I order custom wire nails from WIREHANGERS.US?

Yes. With our in-house U.S. manufacturing facility, we can produce wire nails in custom sizes, finishes, and packaging to match client-specific requirements.