Where to buy Wire Rods in the USA

Where to buy Wire Rods in the USA

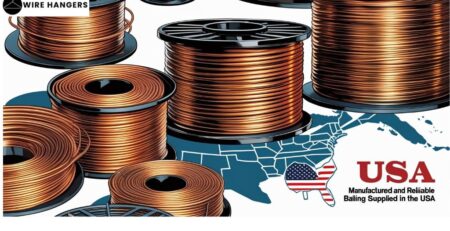

At WireHangers.us, we are a leading manufacturer and exporter of high-quality wire hangers, committed to providing the best solutions for the laundry and dry cleaning industries. We also supply premium SAE 1006, SAE 1008, and SAE 1010 Wire Rods for bulk manufacturing in the United States. With advanced in-house facilities and a skilled workforce, we ensure consistent quality, reliable performance, and global-standard compliance. This guide helps buyers locate reputable sources for wire rods, understand grade-specific advantages, and streamline procurement for wire drawing, fasteners, mesh production, and other applications.

How to find Wire Rods manufacturer and supplier in the USA

- Direct manufacturers with in-house production: Seek suppliers who produce their own wire rods to ensure traceability, consistent chemistry, and tight lead times.

- Domestic distributors with factory-backed partnerships: Reputable distributors can offer a broad range of sizes, coil weights, and packaging options while providing documentation and certifications.

- Industry-standard suppliers: Choose vendors who provide material test reports (MTRs), tensile data, ductility measurements, and weldability assessments to support quality control and compliance.

- Certified bulk suppliers: Look for mills and distributors with ISO or equivalent certifications, ensuring robust quality management and reliable supply.

Grade-focused considerations for bulk purchases

SAE 1006

- High ductility and excellent formability enable complex shapes and precise bending without compromising integrity.

- Low carbon content ensures good weldability, making it ideal for versatile applications such as nails, screws, binding wires, and delicate components.

- Sourcing tip: Prioritize suppliers with consistent low-carbon grades and strong certification packages to ensure uniform bendability and fracture resistance.

SAE 1008

- Balanced strength and malleability provide reliability in performance without sacrificing flexibility.

- Low carbon content enhances weldability, supporting efficient joining processes in manufacturing environments.

- Sourcing tip: Seek mills that offer precise coil weights and tight diameter tolerances to support cold-heading and forming processes.

SAE 1010

- Moderate carbon content offers a higher level of hardness and durability for high-strength needs.

- Excellent machinability and weldability support efficient production workflows.

- Sourcing tip: Confirm batch-to-batch consistency and scalable supply for long production runs.

What to verify when buying bulk Wire Rods

- Certification and traceability: Request material test reports, chemistry data, and mechanical property data for each batch.

- Coil sizes and packaging: Ensure coil weights, diameters, and packaging meet your production line requirements and handling capabilities.

- Lead times and logistics: Confirm production schedules, shipping options, and consolidation opportunities for multiple orders.

- Quality assurance processes: Look for mills with standardized testing for ductility, tensile strength, weldability, and surface quality.

- Customization options: If you need specific tolerances or special finishes, verify the supplier’s ability to accommodate.

Why WireHangers.us as your bulk Wire Rods partner

- In-house manufacturing excellence: Our facilities enable tight process control and consistent material properties across SAE 1006, 1008, and 1010 grades.

- Global standards, local service: We align with international specifications while offering responsive U.S.-based support, expedited shipping, and flexible terms.

- Comprehensive documentation: We provide complete certifications, test data, and technical guidance to help you optimize your production.

- Customization and bulk scheduling: We can tailor coil weights, diameters, tolerances, and packaging to fit your operational needs and lead-time requirements.

How to initiate a bulk order

- Define your application and grade: Choose SAE 1006, 1008, or 1010 based on required ductility, strength, and weldability.

- Specify sizes and packaging: Determine preferred coil weights, diameters, and any coating or finishing needs.

- Request documentation: Ask for MTRs, tensile data, and weldability reports for your records.

- Confirm logistics: Set delivery timelines, shipping terms, and packaging standards for bulk procurement.

- Place the order: Coordinate payment terms, samples if needed, and a schedule that aligns with production

Conclusion

Sourcing high-quality wire rods in the USA is crucial for maintaining efficiency, reliability, and product excellence in your manufacturing or industrial processes. WireHangers.us stands out as a trusted partner, offering precisely engineered SAE 1006, SAE 1008, and SAE 1010 wire rods produced in our advanced in-house facilities. Our commitment to consistent quality, full traceability, and global standards means you receive materials that meet your exact specifications and operational demands. With flexible coil sizes, comprehensive certifications, and responsive support, we help you streamline procurement and ensure your supply chain runs smoothly.

Don’t compromise on quality or service—Contact WireHangers.us today to discuss your bulk wire rod requirements or customized solutions. Let us help you build stronger, more durable, and better-performing products with confidence. Your project deserves the best, and so do you.

FAQ

- Where can I buy wire rods in bulk in the USA?

- Reputable manufacturers with in-house production, plus authorized distributors and industry-approved suppliers, typically offer bulk SAE 1006, 1008, and 1010 wire rods with certification packages.

- What certifications should I expect?

- Material test reports (MTRs), chemical composition data, tensile strength figures, ductility measurements, weldability assessments, and batch traceability documentation.

- How do I choose the right grade for my application?

- SAE 1006 for maximum ductility and formability; SAE 1008 for a balance of strength and malleability; SAE 1010 for higher strength and durability.

- What coil sizes are available?

- A range of coil weights and diameters to fit drawing, forming, and finishing processes; customization is often available for bulk projects.

- Can WireHangers.us customize packaging and lead times?

- Yes, we offer tailored coil specifications, packaging options, and logistics planning to align with production schedules.